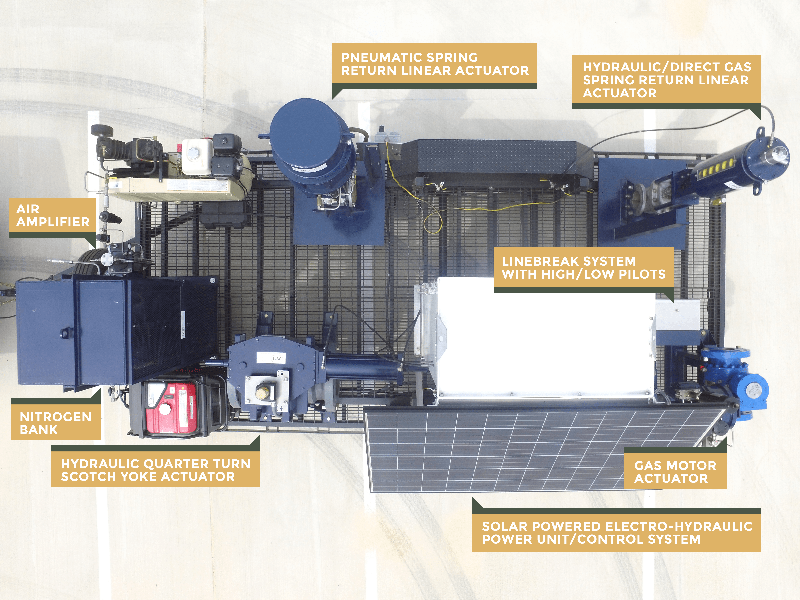

ATI manufactures quality valve automation products built entirely in-house and customized to suit our customers’ specific requirements. To display our broad product line effectively, ATI has created a compact, mobile trailer containing working valve-mounted actuators powered by hydraulics, pneumatics and electronic controls. The demonstration unit allows our customers to appreciate the craftsmanship and quality that go into an ATI actuator or control package to solve complex applications and unique operating conditions.

The demonstration unit enables ATI sales and service team to exhibit and discuss our product line in a variety of settings. The unit is already scheduled to be used for field training, at office ‘Lunch and Learn’ presentations, and at regional trade shows. ATI’s Frontline Services experts will use the trailer to demonstrate field repairs, including calibration services and retrofitting of controls.

The initial unit is equipped with a hydraulic/direct gas spring-return linear actuator, pneumatic spring-return linear actuator, gas motor actuator, solar electro-hydraulic power unit/control system, hydraulic quarter-turn actuator, line break detection control system, and nitrogen power reserve unit .

Depending on the intended audience, the trailer can be easily reconfigured to include many other ATI products including gas-over-oil actuators, double-acting pneumatic and hydraulic linear actuators, pipeline station by-pass controls and other control and power systems.

Learn more about the ATI mobile exhibition and information unit, and schedule a demonstration at a company site. Contact us at sales@atiactuators.com or 713/934-0171.

FAQ:

1. What are Pneumatic, Electrical and Hydraulic Actuators?

There are three types of actuators, based on their source of energy. These include –

- Pneumatic Actuators – These actuators are designed to convert compressed air energy into mechanical motion through a pneumatic control valve. This motion is usually linear or rotatory.

- Electrical Actuators – As the name suggests, these actuators are powered by a motor that helps convert electrical energy into mechanical torque. Thanks to the ready availability of electricity, electric actuators are considered to be the cleanest actuators.

Hydraulic Actuators – These actuators make use of hydraulic power to enable mechanical motion in the form of linear, rotatory or oscillatory motion.

2. What are the benefits of Pneumatic Actuators?

Some of the most prominent benefits of Pneumatic Actuators include –

- Anti-corrosion design, especially when control air is used

- Relatively cost-effective

- High stroking velocities

- Fail-safe outages

- Simple explosion proofing

3. What are the benefits of Electric Actuators?

Some of the remarkable benefits of Electrical Actuators include –

- Accommodating to large distance to the source of energy

- Easy availability of accessories and parts

- Convenient interlocking of signals

- High accuracy

- Great regulation control

- Large actuating force

- Easy remote control and monitoring

4. What are the benefits of Hydraulic Actuators?

Some of the noteworthy benefits of Hydraulic Actuators include –

- High actuating forces

- High stroking velocities

- High stability